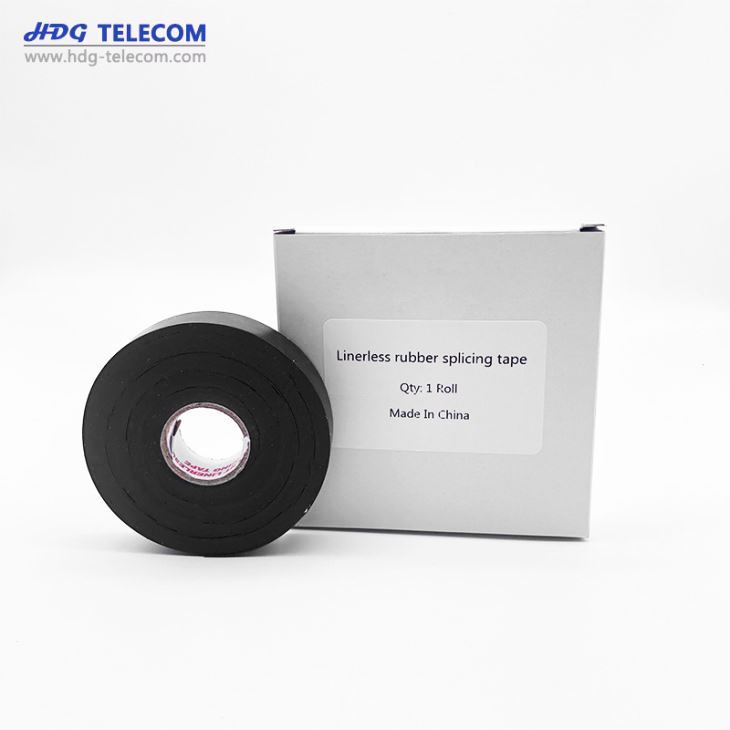

Linerless Self-Amalgamating Rubber Splicing Tape

Item No.: WT-RT-130C / Material: EPR / Regular Size:0.76mm*9.1m*19/25/38mm

Category:

Tape

Keywords:

Linerless Self-Bonding Tape

3M 130C Tape

Contact

Product Description

|

Description |

No lining insulation, flame retardant self-adhesive tape, the substrate is ethylene propylene rubber, excellent flame retardant properties. Rated up to 90˚C continuous operating temperatures and short-term 130˚C overload service. It can be used for the insulation, flame retardant and heat dissipation of the cable terminal and the joint, which has excellent electrical performance and can be applied to 69KV

|

Dimensions |

|

Color |

Black |

|

Size |

0.76mm*19mm*9m |

|

0.76mm*25mm*9m |

|

|

0.76mm*38mm*9m |

|

|

Other size can be customized as your requirement. |

|

|

Specification |

|

Property |

Value |

Test Method |

|

Thickness |

0.8 mm |

ASTM D4325 |

|

Tensile strength |

1.34 Mpa |

ASTM D412-06 |

|

Elongation at break |

1200% |

ASTM D412-06 |

|

Anti ozone aging (50*10-8, 40℃*24h,free state placement) |

0 grade (No crack) |

ASTM D4325 |

|

Dielectric Strength (KV/mm) |

26.5 KV/mm |

ASTM D4325 |

|

Dielectric Strength (normal temperature*24h,medium:distilled water) |

25.5 KV/mm |

ASTM D4325 |

|

Dielectric Strength (23℃*RH96%*96h) |

21.2 KV/mm |

ASTM D4325 |

|

Dielectric constant |

2.9 ε |

ASTM D4325 |

|

Dielectric constant(90℃*24h) |

2.8 ε |

ASTM D4325 |

|

Flame Rating(Vertical) |

V-0 |

UL94 |

|

Xenon-arc exposure @200h |

Pass |

ASTM D4325 |

|

Feature |

· Linerless, self-bonding primary insulating tape rated up to 69 kV.

· High thermal conductivity.

· Flame retardant.

· Excellent physical and electrical properties.

· Physical and electrical properties unaffected by degree of stretch.

· Compatible with common, solid dielectric cable insulation.

· Designed to insulate splices and terminate cables whose overload temperatures can reach 130°C.

· Wide range of temperature.

· Weatherproofing.

|

Application |

· Primary insulation for splicing all types of solid dielectric insulated cables up to 69 kV.

· Up main insulation 35KV solid medium cable stress cone when making application.

· Intermediate joint and terminal protection.

· Moisture seal for electrical connection.

· Bus insulation.

· Cable end sealing.

· Wire for electric motor.

· Jacket repairs.

|

Installation |

1. Should be always successive half-lapped ;

2. The side of the tape wrapped inside the roll should be applied outside on the splice (tacky side up);

3. Use highly elongate the tape in critical areas;

4. Use less elongation in less critical areas;

(Normally, the tape is stretched to ¾ of its original width in these less critical areas)

5.When using tape for splicing cable above 15 kV, always highly elongate the tape throughout the entire splice.

Part Number

Previous

Previous

Feedback

WRITE A MESSAGE TO US

Related Products

Universal Weatherproofing Kit For Connectors And Antennas

Item No.: WK-WT-221213 / Application: Cell tower weather proof / Size/Spc: Detail as below

Add to Inquiry